Concrete is one of the main materials used in building construction. This material is strong in compression but very weak in tension. The compressive capacity is also much lower than that of steel. Steel bars are used inside the concrete to support the tension or reduce the concrete area. The steel bars are very ductile (elongated before failure) and give ample warning before they fail.

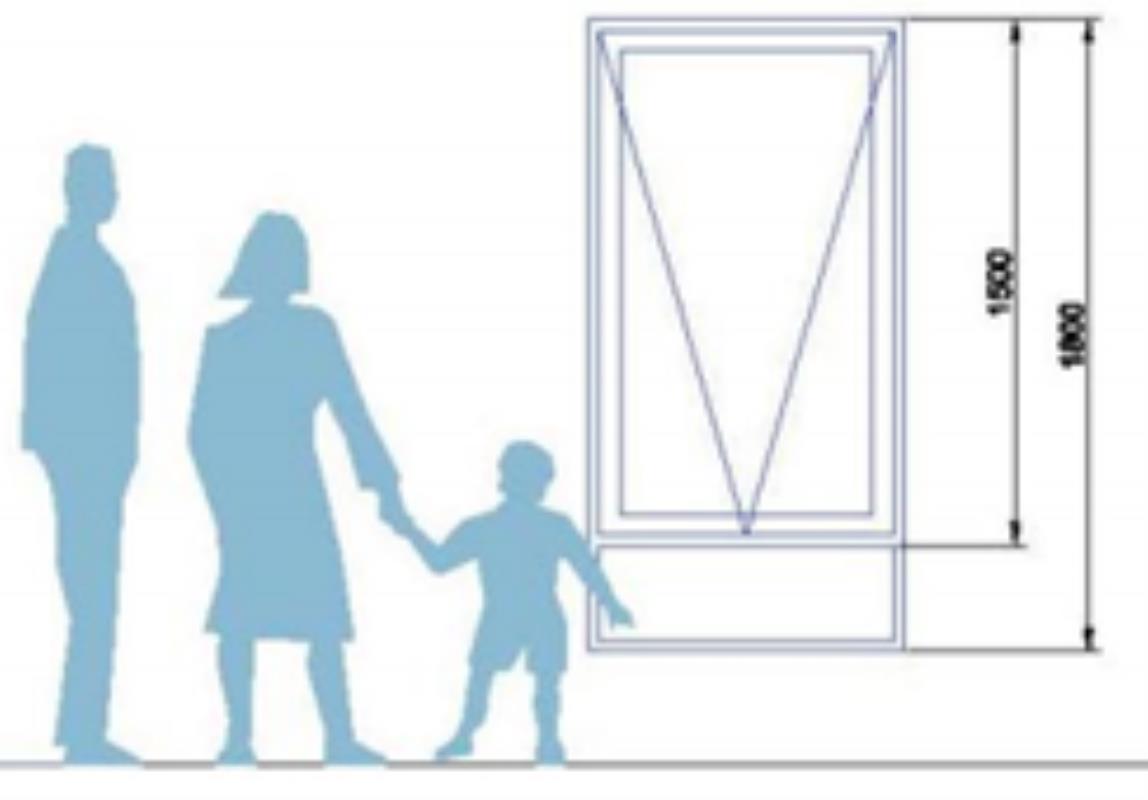

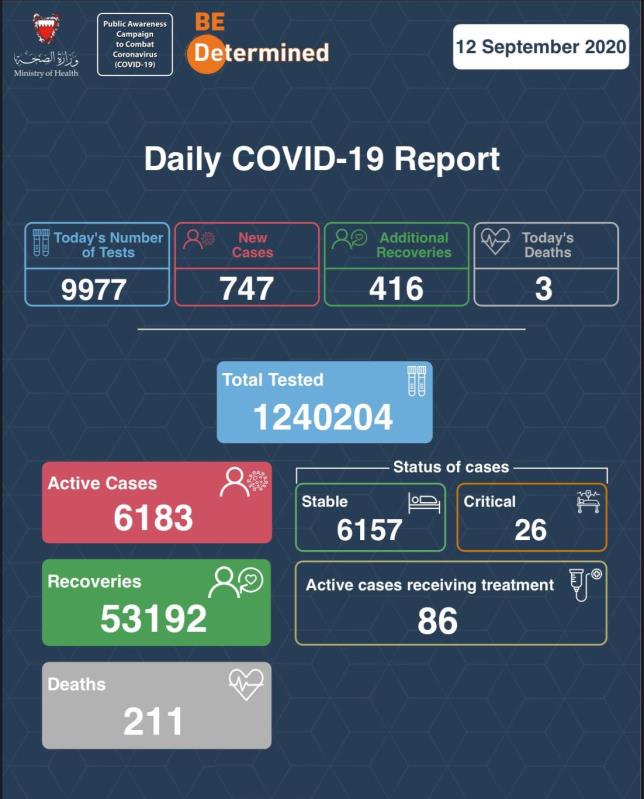

However, these bars are prone to corrosion when they come into contact with moisture. If the concrete is cracked or the concrete cover is flaking for some reason (see Figure 1), the moisture can reach the steel. On the other hand, in offshore structures or structures in damp regions, moisture can penetrate the concrete and reach the steel. The moisture corrodes the steel and consequently the steel loses its strength. This shortens the life of the structure and it takes a lot of money to repair the structures.

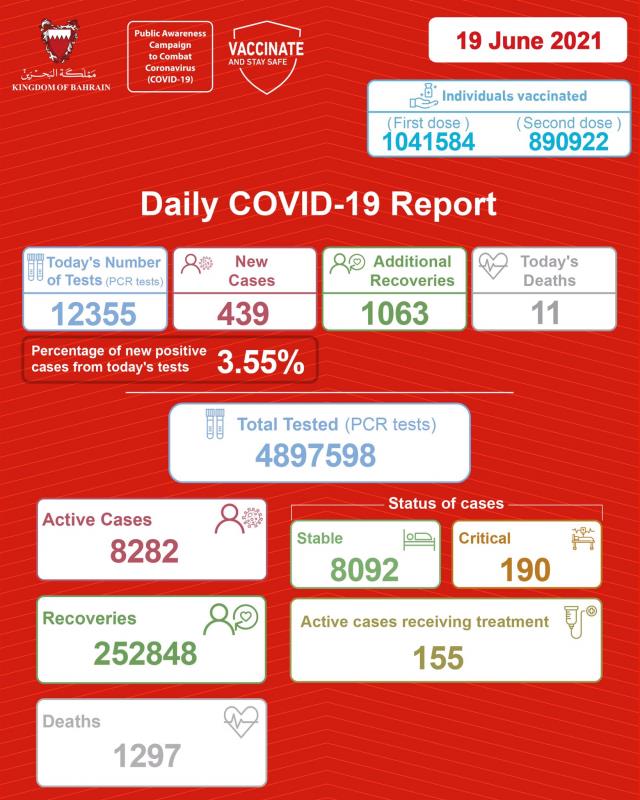

To avoid this problem, fiber reinforced polymer (FRP) bars (Figure 2) have recently been used in some countries as an alternative to steel bars due to some of their favorable properties. These bars consist of fibers that is embedded into a matrix. These are produced using the pultrusion technique. In this technique, the fibers are pulled through a resin bath. After impregnated with resin, these were passed in different stages to provide the desired shapes and to cure the bars. These bars are light in weight, stronger than steel bars, non-conductive to electricity and heat, and have no magnetic affinity. However, these bars show no ductility behavior and suddenly fail. For this reason, the member should be designed in such a way that the concrete fails when it is compressed, as it has better ductility than FRP. Many research has been carried out with FRP as a substitute for steel. It has been found that FRP can be substituted as a reinforcement material to prevent corrosion. A group of Saudi Arabian researcher evaluated the performance of FRP materials for different local environments and confirmed that these materials can be used in new constructions as well as repairing existing structures. Saudi Aramco has recognized the numerous advantages of FRP bars in construction and recently mandated the inclusion of FRP bars in its design standards for non-critical components such as slabs, walkways, drainage channels and sleepers.